A Powerful Solution for Carbon Reduction

Keeping your existing infrastructure

While reducing carbon emissions

And maintaining a reliable baseload and peak power supply.

Installing a compact JFT-1000 system on-site

And removing carbon from natural gas before combustion

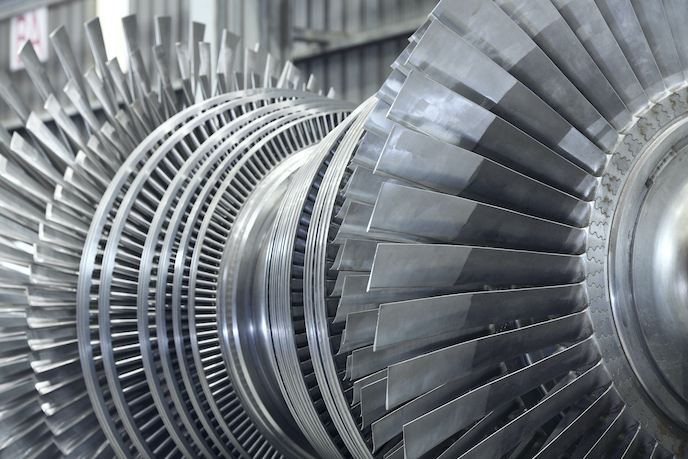

Upgrading your plant with clean burning hydrogen

While keeping your existing gas-fired turbines.

Reducing carbon emissions on day one

While meeting or exceeding EPA emission standards.

Maintaining reliable baseload power generation

While ensuring plant operations continue without interruption.

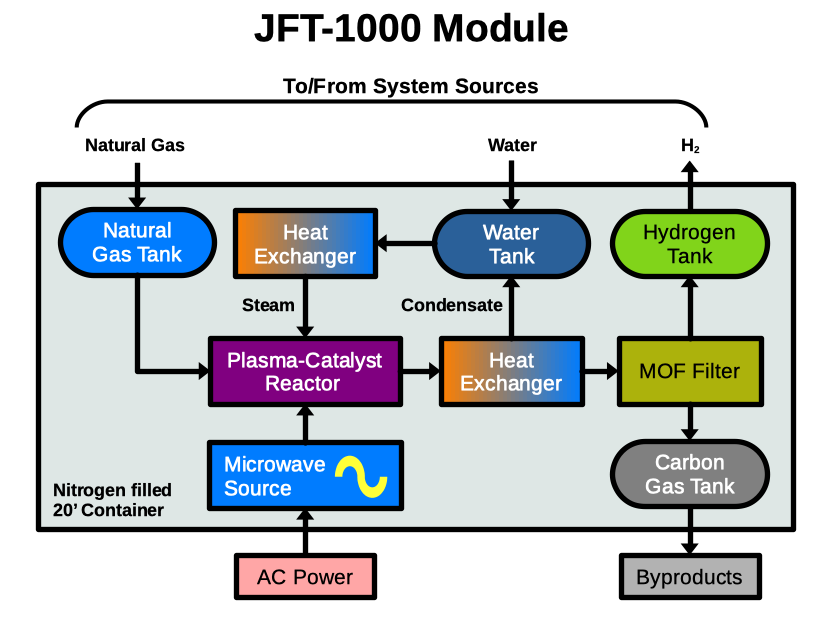

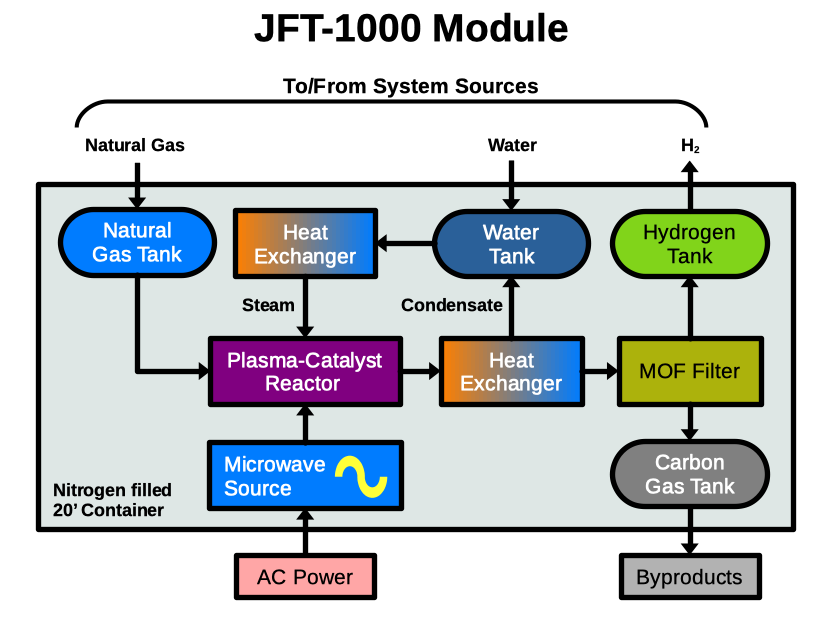

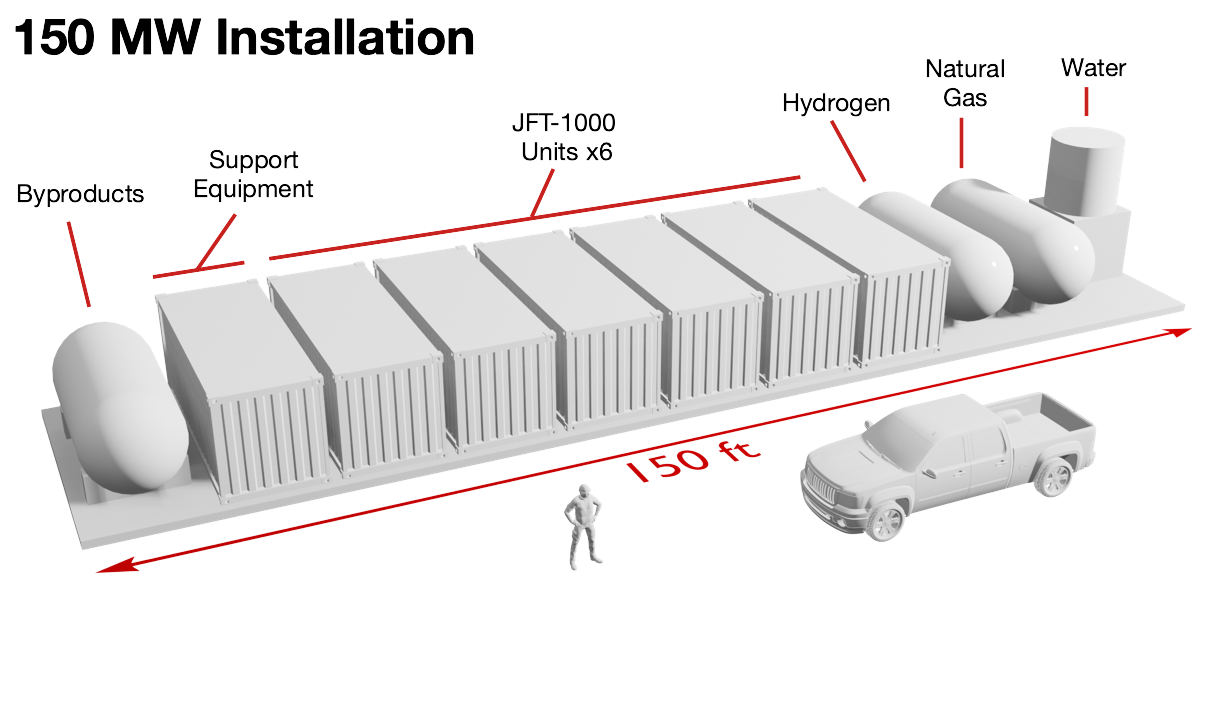

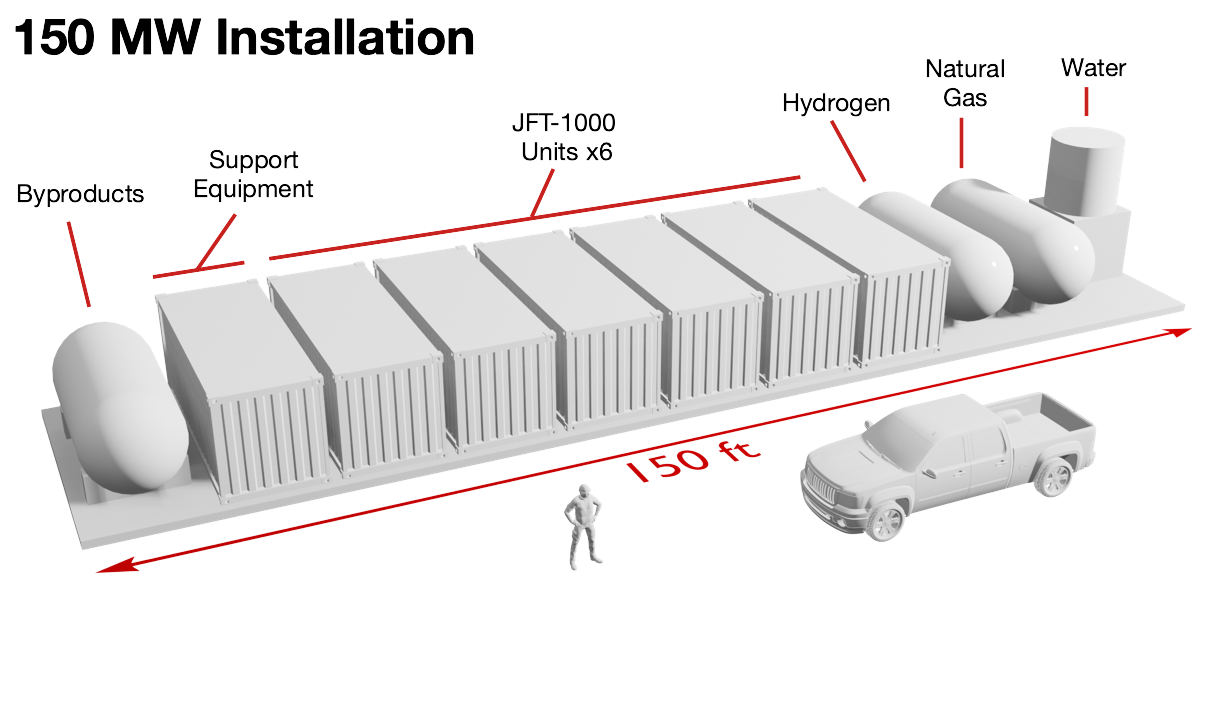

The JFT-1000 Module transforms natural gas and water into hydrogen fuel and carbon compound byproducts. The hydrogen fuel mix can power existing natural gas-fired turbines. Modules can be clustered, with each producing enough hydrogen to fuel a 25-megawatt power plant. The carbon compound byproducts are used in industrial processes.

JFT's process reacts natural gas and steam in a catalytic microwave-plasma reactor producing hydrogen and carbon compund gases. The resulting gases are passed through a MOF filter which separates the carbon compound gases from hydrogen fuel.

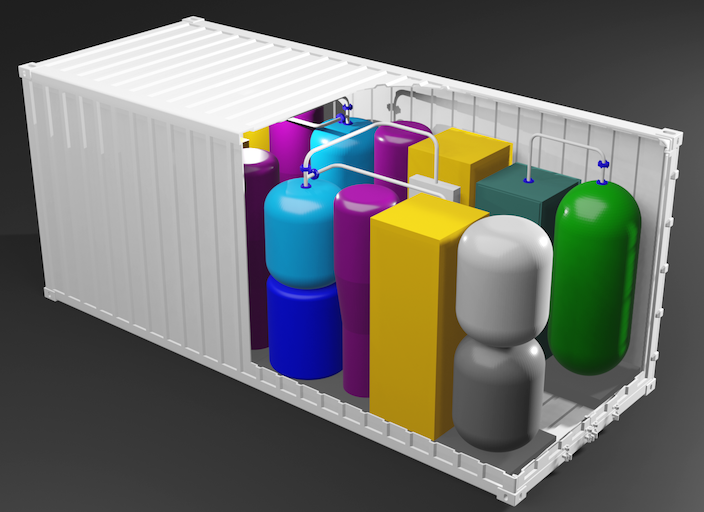

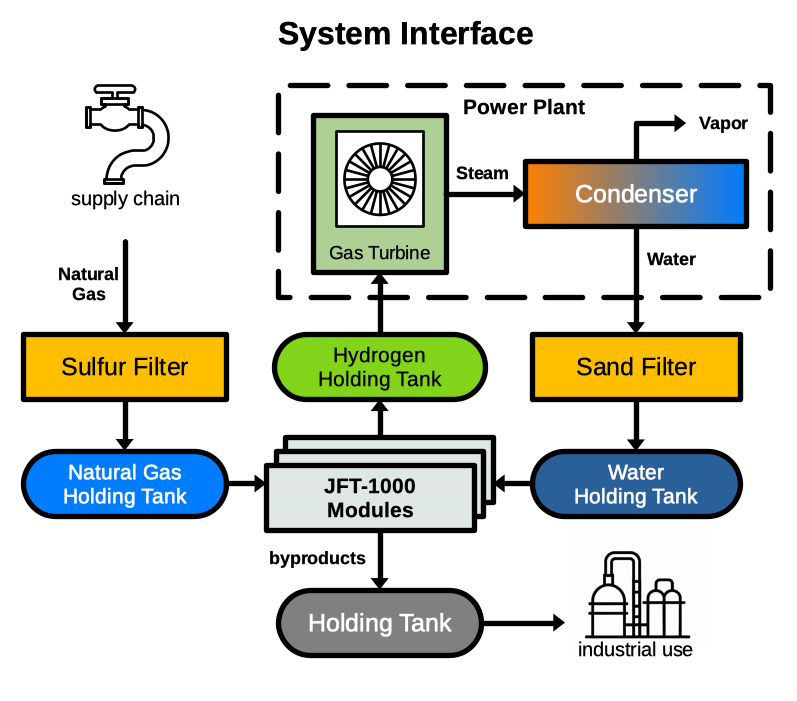

A JFT installation minimizes interfaces with existing power plant equipment. Your plant supplies natural gas, water, and A/C power. JFT's system includes holding tanks for natural gas and water, where sulfur compounds are removed and solids are filtered. Pressurized hydrogen is held before being piped to the plant's turbines. Byproduct carbon compounds are held in tanks for third party collection.

You benefit from JFT's small footprint. A typical installation easily fits an unused corner of a parking lot. Equipment comes prefabricated in standard 20-foot containers. Only manifolds and holding tanks are assembled on a site-specific concrete pad. Installation can be completed in several weeks and should not interrupt the power plant's operations. Final interconnections take only a few days.

Please tell us how we can help, what are your requirements?